Välkommen till Globträdet

Globträdet har vuxit ur en fråga

som Globteatern fick av en 8-årig flicka

” Tror ni att vi har någon framtid?”

som Globteatern fick av en 8-årig flicka

” Tror ni att vi har någon framtid?”

Men det började med…

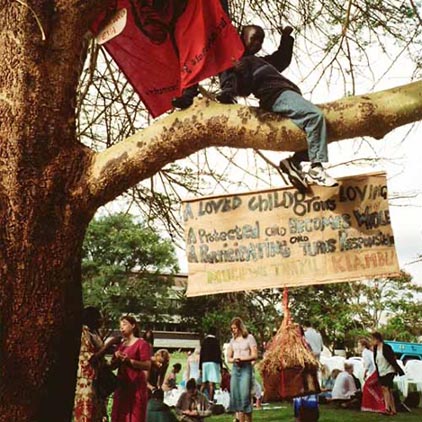

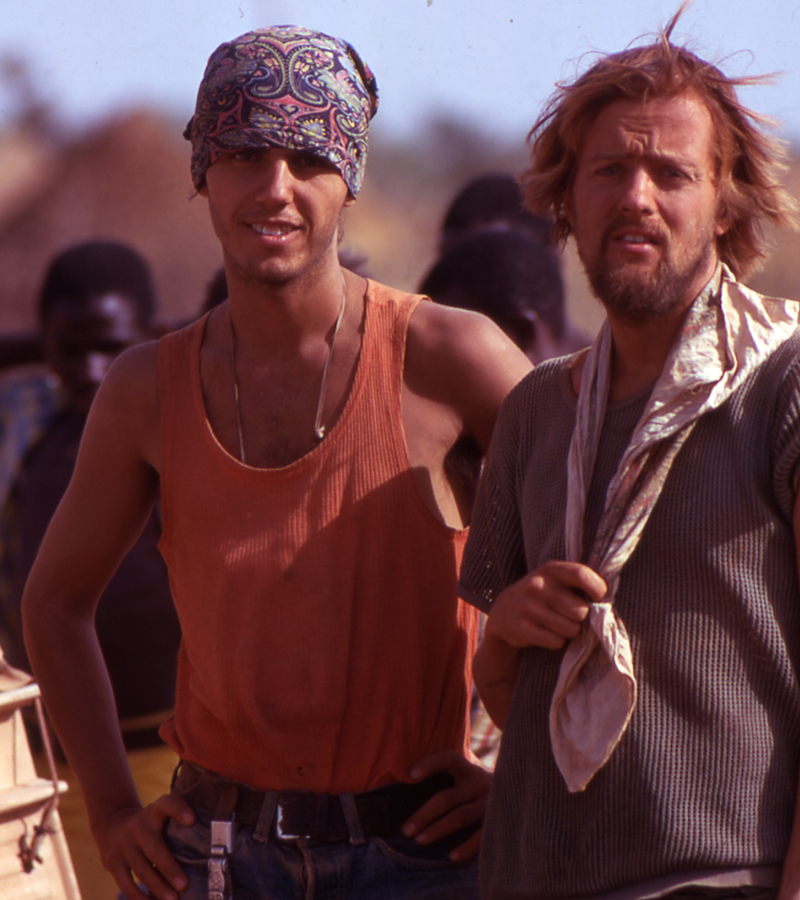

vandringar jorden runt

teaterturnéer

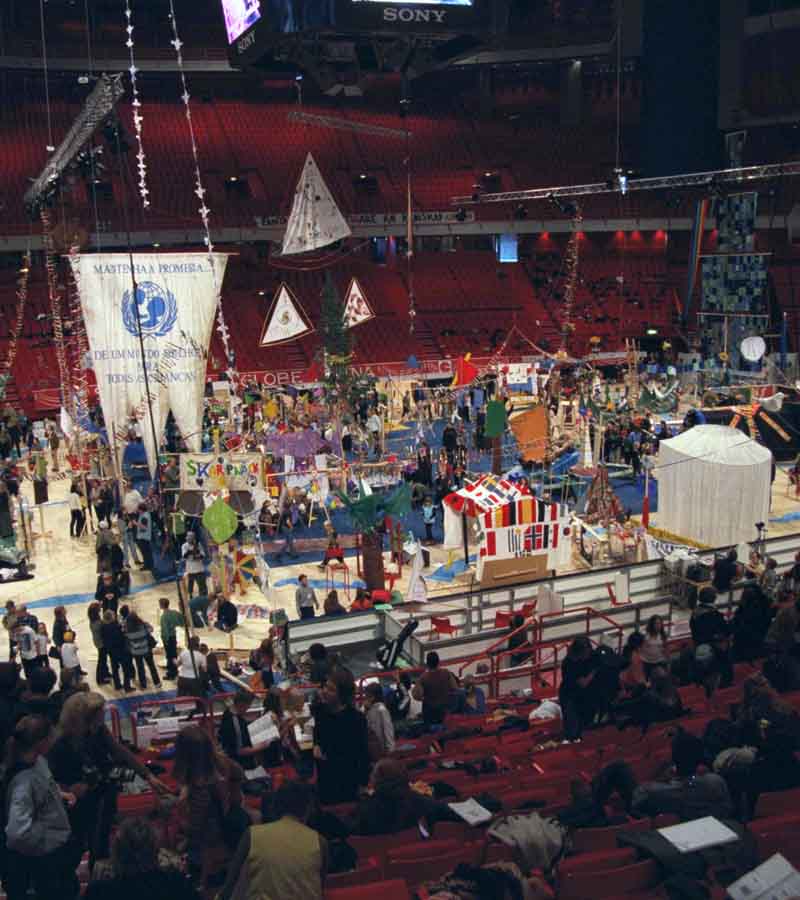

… och ett jättebygge i Globen

och det växte och växte…

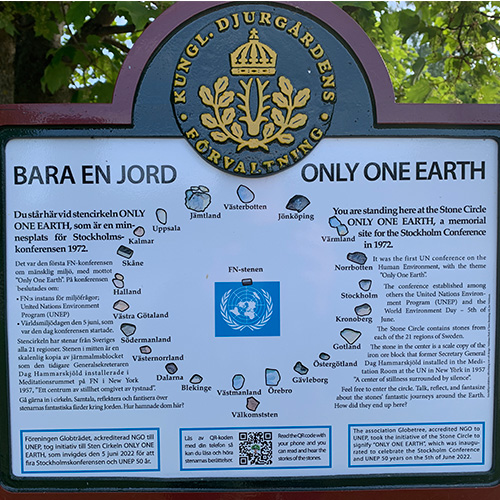

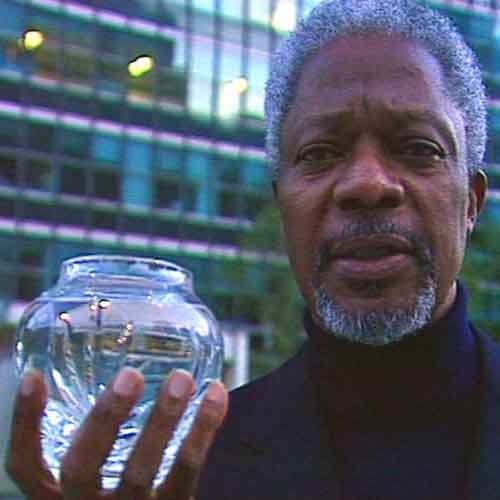

2nd World Water Forum i Haag, Holland

Stockholm 750 år firades med barn från 30 länder

Första VM i Samarbete i Globen

Andra VM i Samarbete Kampala, Uganda

En hälsning från Kenya – två flickor berättar

Inlägget finns också på:

Engelska

Engelska